Demolishing a building is no small task. But when that building has post-tensioned concrete, the stakes get even higher. Their demolition demands a level of precision and expertise that most contractors aren’t equipped to handle.

If you’re a property owner planning a large demolition project, you need to be aware because improper handling can lead to serious safety hazards, skyrocketing costs, and unexpected delays.

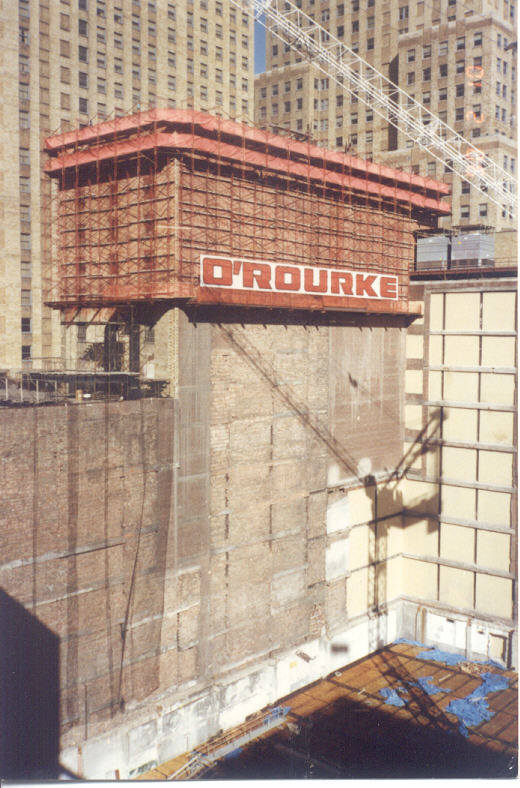

In this helpful guide, we’ll break down what makes post-tensioned concrete unique, why it requires specialized demolition techniques, why O’ROURKE is the right partner for your demo project.

What Is Post-Tensioned Concrete?

Post-tensioning is a construction technique where steel cables, also called tendons, are embedded in concrete and then stretched tight after the concrete has hardened. This process creates compressive forces, allowing the structure to withstand heavy loads or span greater distances without the bulk of traditional reinforced concrete.

So, why was post-tensioning so popular? In its peak during the 1960s, it was a cost-effective solution for creating durable, lightweight structures. The reduced weight made construction faster and cheaper, while the added strength allowed for innovative designs.

However, its popularity declined as new materials and construction methods emerged. Today, post-tensioned structures still exist, but many are reaching the end of their lifespan. This means they’re often prime candidates for demolition—and O’ROURKE has the expertise to handle these projects with the care they demand.

Key Features of Post-Tensioned Concrete

What makes post-tensioned concrete so unique? It’s all about those tensioned cables. Imagine a rubber band stretched to its limit and held in place—that’s the essence of post-tensioning. This method distributes stress more evenly throughout the concrete, reducing cracks and making the structure more durable over time.

However, those same cables can pose a challenge when it comes to demolition. They store a tremendous amount of energy, which can release unpredictably if not handled correctly. This isn’t something you’d want to approach without proper training or tools. It’s a double-edged sword: what makes the material strong during construction becomes a potential hazard during demolition.

Structures with Post-Tensioned Concrete

You’ve likely encountered post-tensioned concrete without realizing it.

- Parking Garages: Lightweight slabs made it easier to create multiple levels without the need for excessive support columns.

- High-Rise Buildings: The combination of strength and reduced weight allowed for slimmer, taller designs.

- Bridges: Long spans over rivers or highways often relied on post-tensioning to achieve their length.

- Stadiums: The massive beams and supports in sports arenas often use this method for stability and flexibility.

At O’ROURKE, we’ve worked with all types of post-tensioned systems, giving us a deep understanding of the unique challenges they present. Parking garages may have hidden cables that pose safety risks, while bridges might require precise sequencing to avoid catastrophic collapses.

The Challenges of Demolishing a Post-Tensioned Structure

Demolishing post-tensioned concrete isn’t just about brute force. The internal steel tendons—designed to be under extreme tension—make the process significantly more complicated.

Imagine cutting through a post-tensioned slab without knowing where the tendons are. The sudden release of tension could cause the steel to snap violently, sending shards of concrete and metal flying. This isn’t just a theoretical risk; it’s a genuine hazard that puts workers and nearby properties at risk.

Additionally, post-tensioned demolition must account for:

- Unpredictable Behavior: Tendons can behave erratically when their tension is released improperly.

- Structural Dependencies: Cutting the wrong section can lead to unintended collapses elsewhere.

- Public Safety: Demolitions in urban areas need extra precautions to protect pedestrians and adjacent buildings.

Why Specialized Demo Techniques Are Necessary

If you’ve ever seen a traditional concrete structure demolished, you might think it’s a straightforward process. Wrecking balls, excavators, or even explosives can reduce a reinforced concrete building to rubble in hours. But with post-tensioned concrete, it’s not that simple.

- Controlled Release of Tension: You can’t just cut into a post-tensioned beam or slab. The tension in the tendons must be carefully released to prevent dangerous snaps.

- Precision Demolition: Tools like concrete saws and hydraulic breakers are often needed to dismantle sections piece by piece.

- Avoiding Chain Reactions: Improper demolition could destabilize the entire structure, leading to uncontrolled collapses.

- Environmental Hazards: Dust, debris, and potential contamination from corroded tendons require strict management protocols.

This is why hiring O’ROURKE’s demolition experts is critical. Our team has the experience in post-tensioned demolition to know how to approach each structure methodically, prioritizing safety and efficiency.

Health and Safety Considerations

Safety isn’t just a box to check—it’s the cornerstone of every post-tensioned demolition project. From the first assessment to the final piece of debris, precautions must be built into every step of the process.

- Comprehensive Assessments: Every structure is different. Mapping the location of tendons and assessing their condition is critical before any work begins.

- Worker Training: Teams need specialized training to understand how post-tensioning systems work and how to dismantle them safely.

- Protective Equipment: Safety gear like helmets, gloves, and protective shields are mandatory, especially when working with heavy machinery or explosives.

- Compliance with Regulations: Adhering to OSHA and local guidelines isn’t optional—it’s the baseline for safe operations.

Ultimately, safety is about more than protecting workers. It’s about ensuring the project runs smoothly, without accidents or costly setbacks.

Methods of Post-Tensioned Demolition

When it comes to post-tensioned demolition, the method matters. Each structure demands a customized approach, and at O’ROURKE, we tailor our techniques to the specific needs of your project.

Controlled De-tensioning

De-tensioning is the cornerstone of safe post-tensioned demolition. Think of it as carefully disarming a loaded spring. Our team meticulously identifies and releases the tension in steel tendons, section by section.

Mechanical Demolition

For structures that can accomodate heavy machinery, mechanical demolition can be highly effective. Mechanical methods are often used in tandem with de-tensioning to ensure safety and efficiency. Our operators are highly trained to handle these tools with pinpoint accuracy, reducing the risk of unintended damage.

Explosive Demolition

While less common, explosive demolition can be an effective option for certain post-tensioned structures, such as large bridges or stadiums.

O’ROURKE’s Expertise in Post-Tensioned Demolition

At O’ROURKE, our team is made up of seasoned professionals who understand the complexities of post-tensioned structures. From engineers to equipment operators, every member of our team plays a critical role in ensuring the project’s success.

We also invest heavily in ongoing training, ensuring that our crew stays up-to-date on the latest techniques and safety protocols. This dedication to expertise is one of the many reasons why property owners trust O’ROURKE with their most challenging demolition projects.

Request a Consultation Today

Every successful post-tensioned demolition starts with a solid plan. At O’ROURKE, we leave nothing to chance. From the initial assessment to the final debris removal, our process is rooted in meticulous preparation. Ready to get started? Contact O’ROURKE to schedule a consultation.